Flosense 1.0 system

> Measurement and control from 1 or 2 sensors (supply and return)

> Measures the three quantities of flow, temperature and pressure.

> Display and recording of delta t

> Display and recording of delta p

> Alarm output

> Data logging and export

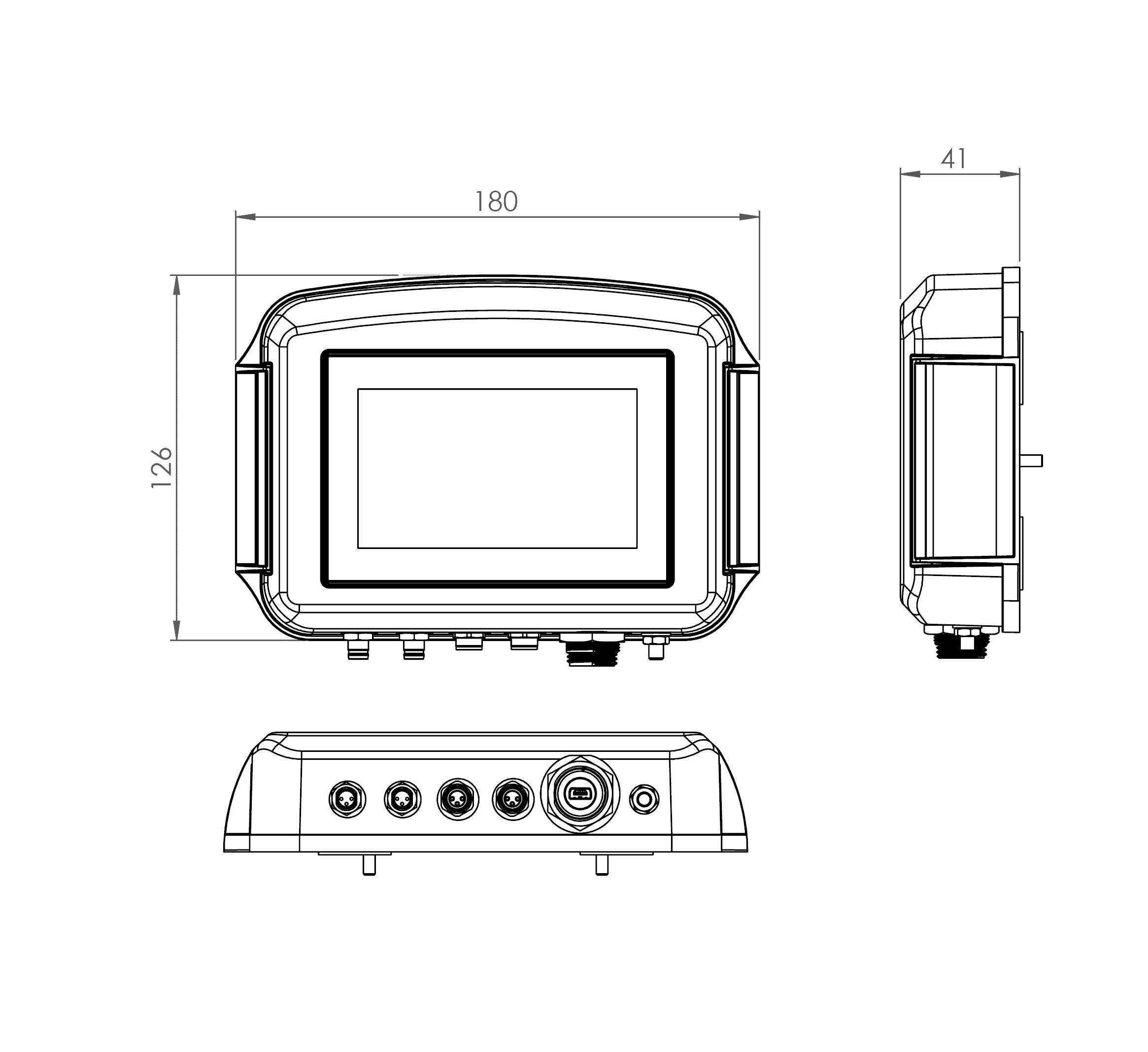

Touch screen display

Display of Reynolds number (flow characteristics)

The reading and recording of the flow, temperature and pressure data will allow a global analysis of the process to the operator.

The installation of 2 sensors at the inlet and outlet of the mold allows the measurement and recording of the delta p and delta t which are the most important characteristics of the regulation process.

It is possible to check the regularity of the heat exchange and the possible instability of the pressure which characterizes leakage or clogged circuits.

The flosense system can be installed on the press thermoregulator, on a critical circuit of the mould, on the mould feeders or on the general supply of the plant.

-

FlosenseSystème Flosense 1.0The Flosense system has been designed to accurately measure variations in flow, temperature and pressure in cooling systems. Download documentation See the product

-

Flosense

Système Flosense 1.0

Système Flosense 1.0The Flosense system has been designed to accurately measure variations in flow, temperature and pressure in cooling systems. Download documentation See the product