Servomold

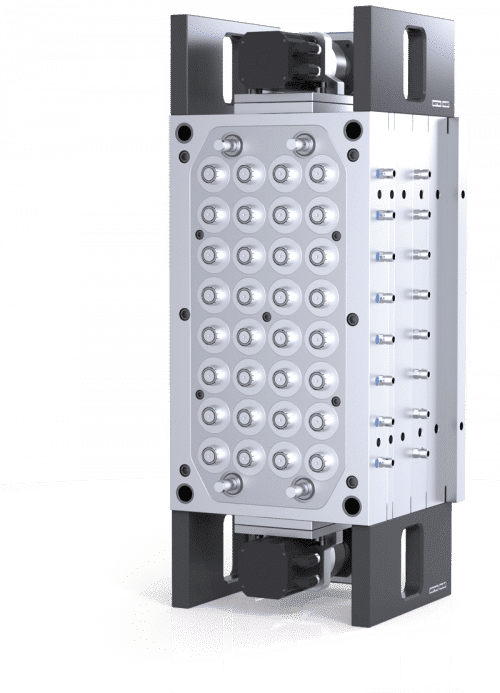

System solutions from Servomold convince because of precision, reliability and durability. To achieve this, despite the large number of complex parameters in the injection molding process, we leave nothing to chance.

Our project engineers will accompany you from the beginning in the development and design process of your injection molding tool – they ask the right questions and work out the best possible solution – individually and tailored to your requirements ...

Read more

> Unscrewing concepts from 1x to 96x and more

> Gearbox concepts and calculations

> Design and calculation of the drivetrain

> Lifetime calculation of bearings, gearwheels and timing belts